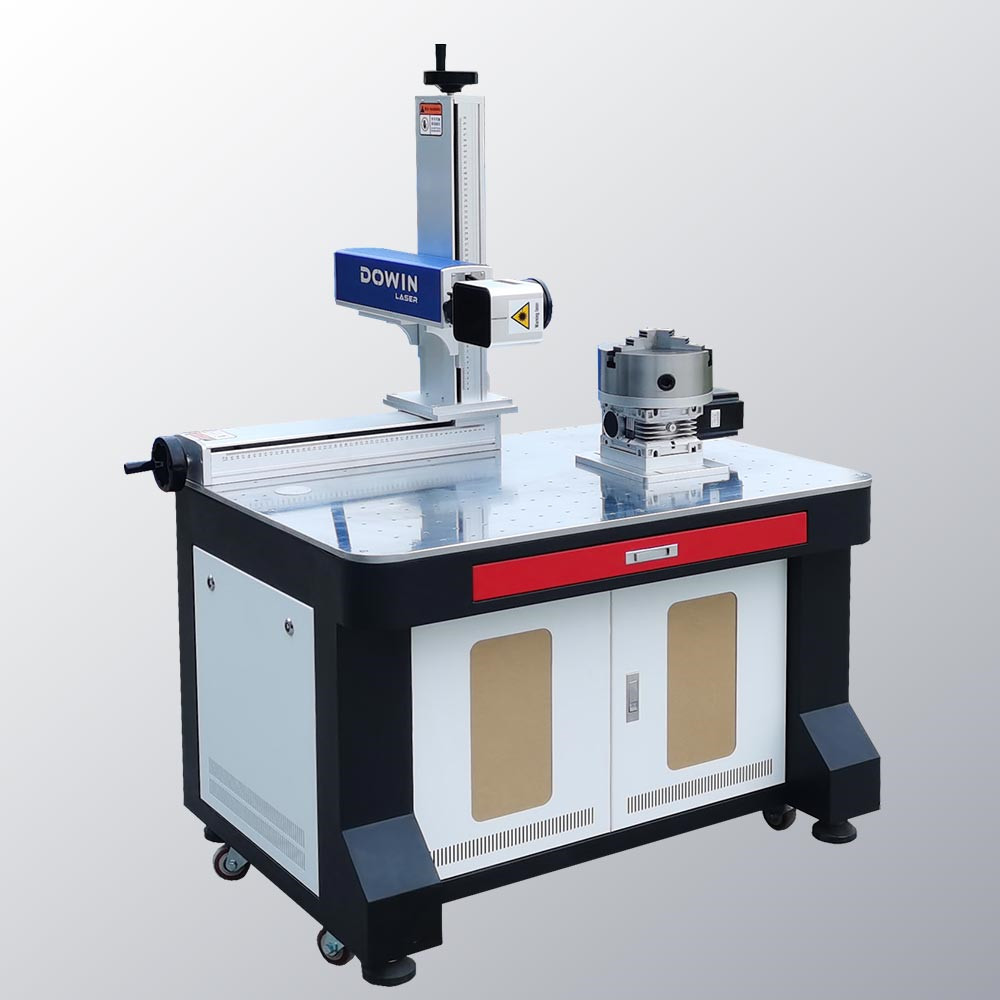

Wholesale Aluminum Laser Welder - 400W 600W Automatic YAG laser welder for mould refurbishing – Dowin Detail:

Features

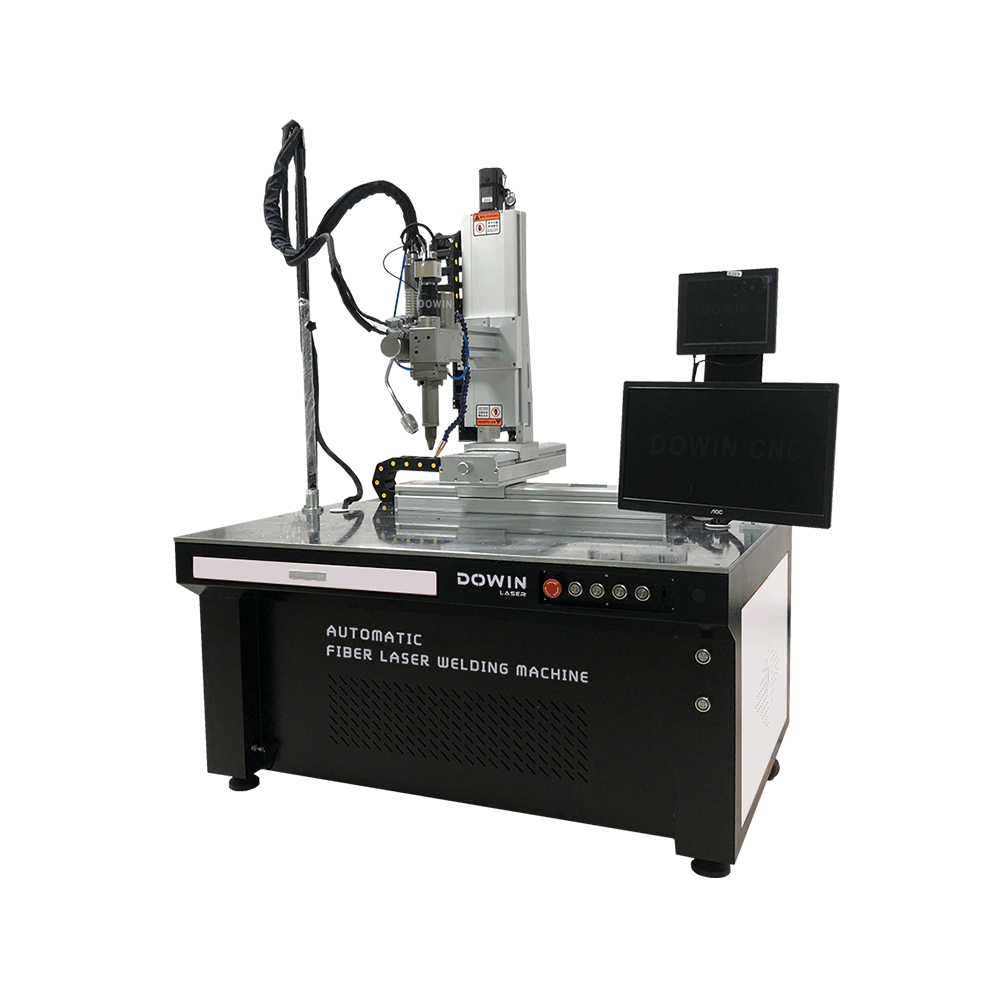

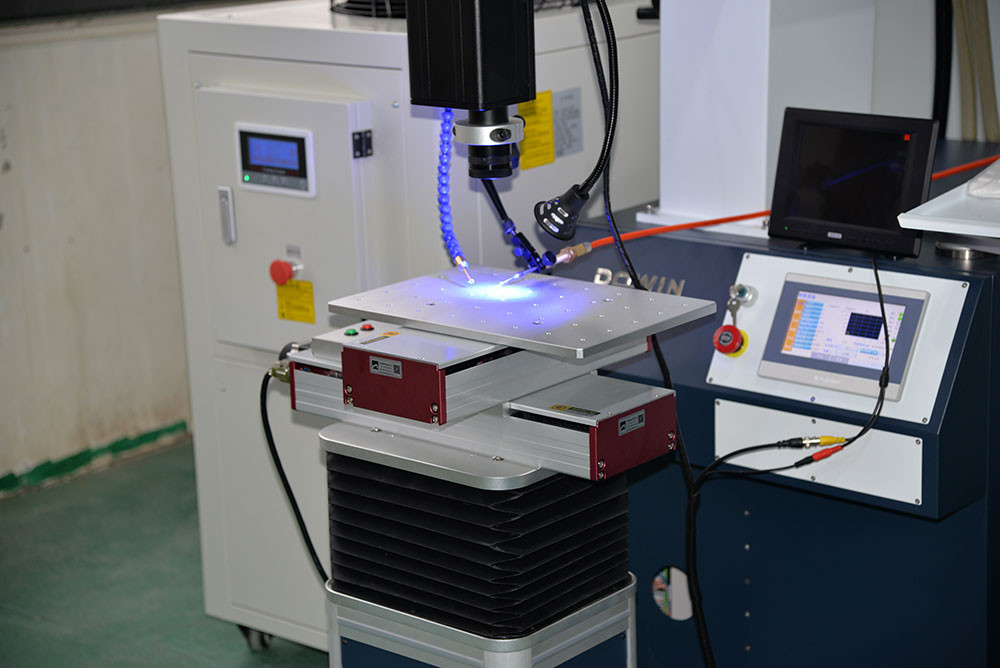

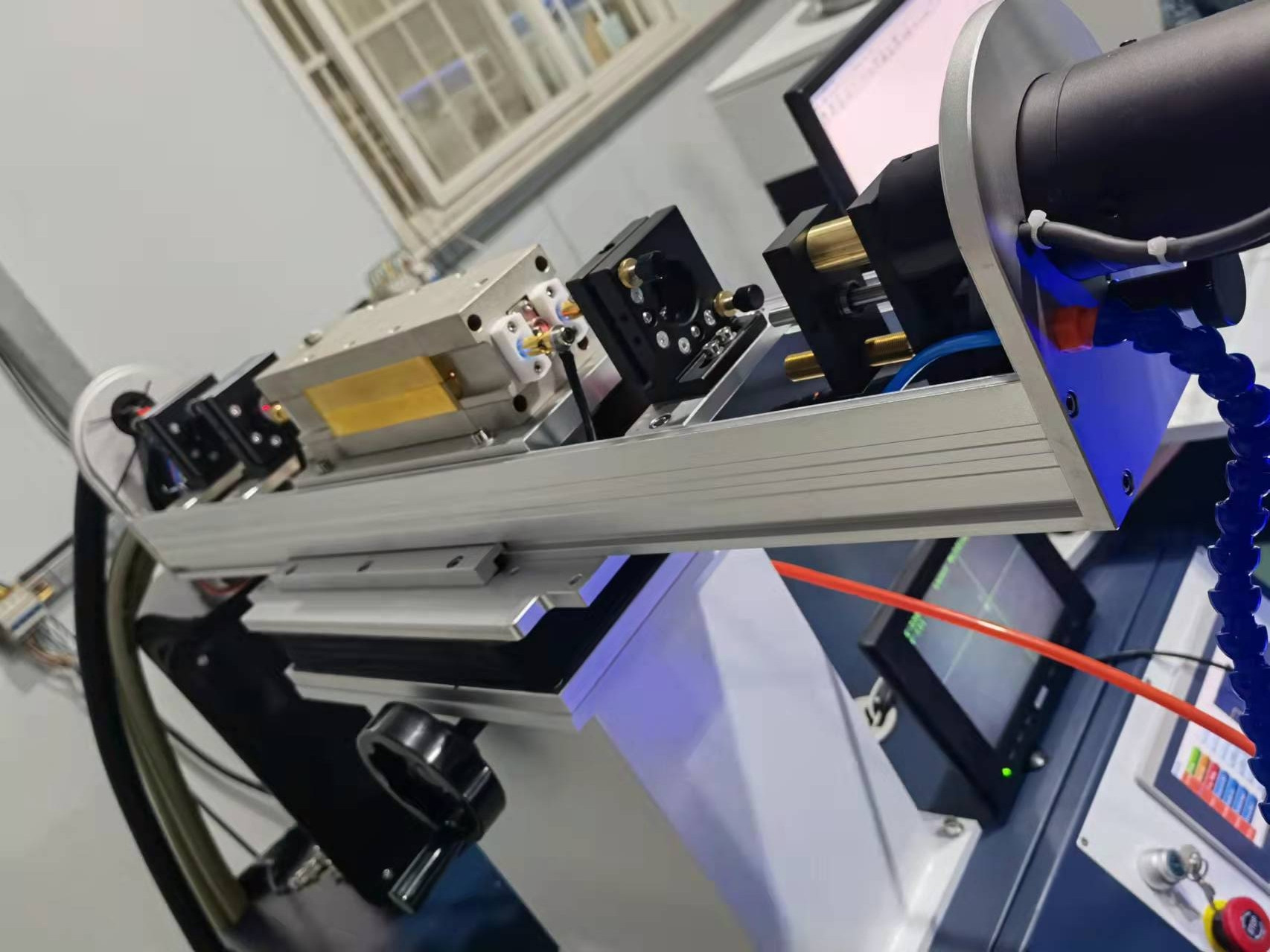

● This Automatic laser welder use electric XY Working table, auto focus laser head ,could welding on curving surface controlled by software.when use Rotary, it is 4 axis automatically ,Could add Automatic wire feeding system.

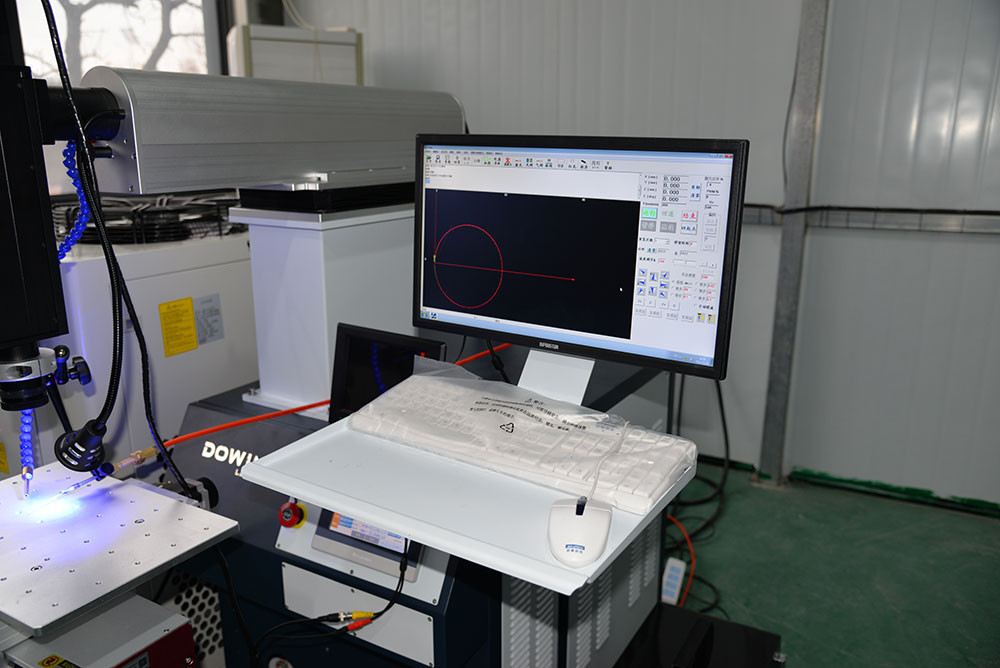

● CNC2000 Software and computer and CCD viewing system free with machine.

● Output power, frequencies, the pulse width and other parameters of the Laser set up directly in system.

● PLC controls Workbench moving speed & directions (forward, backward, left or right), produce a flat and tidy welding line or welding point to optimize the results.

Video introduction

Please check Video to see more details and how it works introduction:

Tech Specifications

|

Models |

DW- 400A DW-600A |

|

|

Travel Path(X, Y, Z) |

X=300mm ,Y=200mm,Auto X & Y Axis and focus control by software .Electrical adjust Z Axis. |

|

|

Worktable Bearing Load |

100KG |

|

|

Machine Weight |

380kg 450kg |

|

|

Power Supply |

220V±10%/50Hz/60Hz / 380V±10%/50Hz/60Hz |

|

|

Laser Type |

Nd:YAG Pulse |

|

|

Laser Spot |

0.1-3mm |

|

|

Wavelength |

1064nm |

|

|

Pulse Width |

0.5-25ms |

|

|

Max. Average Power |

400W 600w |

|

|

Whole Power |

12KW 17Kw |

|

|

Pulse Frequency |

0-100Hz |

|

|

Focusing Size |

110mm |

|

|

Chiller |

Water Cooling System Bingyue 2.8KW chiller |

|

|

Observing System |

CCD |

|

|

Protective Gas |

Argon |

|

|

Welding Wire Dimension |

0.1-1.0mm |

|

Gold coated metal cavity, ensure long life span and strong power

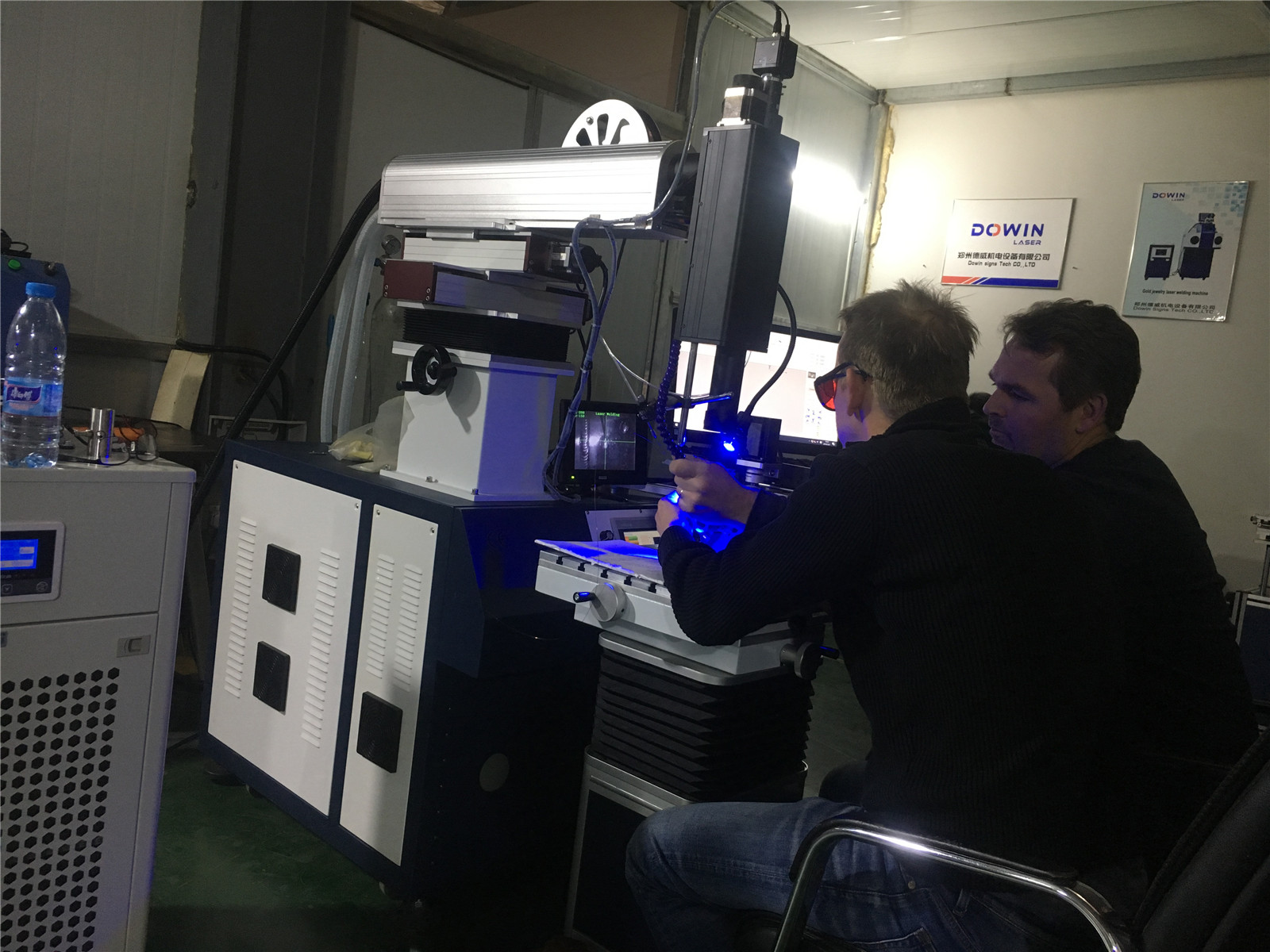

Offer free factory training

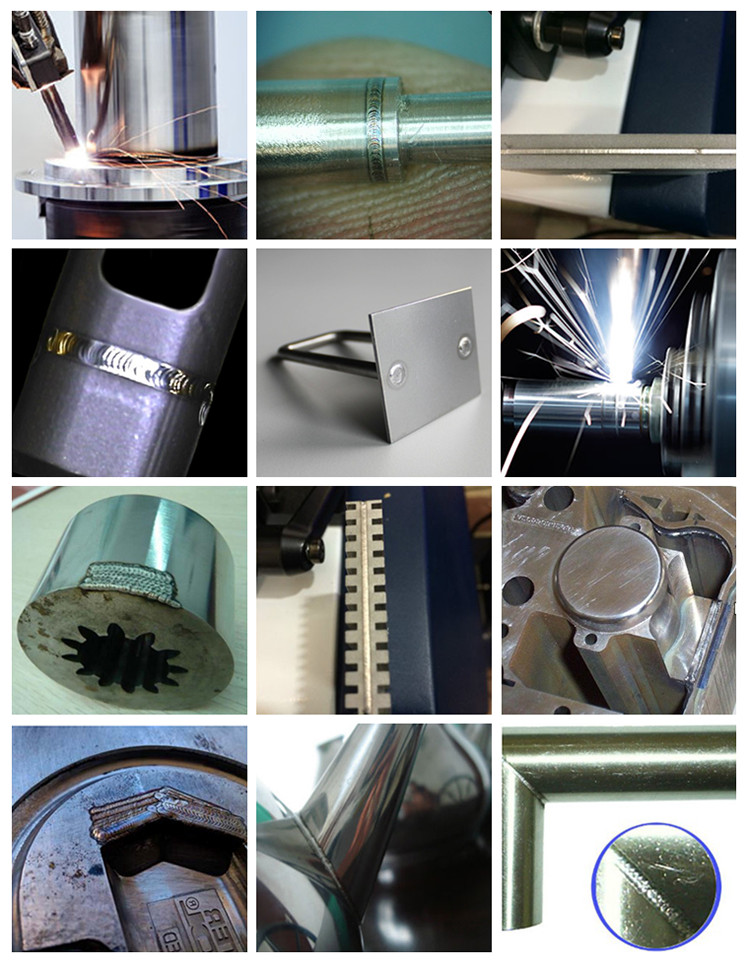

Application materials

1.What material do you need to laser process?

2.Do you need wire feeder

3.Could you send materials to us for free testing?

4.Your company name, website, Email, Tel (WhatsApp…)?Are you reseller or need it for your own business?

5.How do you want to ship it , whether do you have your own forwarder?

Product detail pictures:

Related Product Guide:

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Wholesale Aluminum Laser Welder - 400W 600W Automatic YAG laser welder for mould refurbishing – Dowin , The product will supply to all over the world, such as: Jordan, Las Vegas, Algeria, Welcome to visit our company and factory, there are various products displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to provide you the best service

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.