Laser ho betla le ho seha patsi, MDF, letlalo, lesela, acrylic, rabara, polasetiki, PVC, pampiri, epoxy resin, bamboo.

Khalase e betliloeng, ceramic, marble, lejoe le tšepe e koahetsoeng.

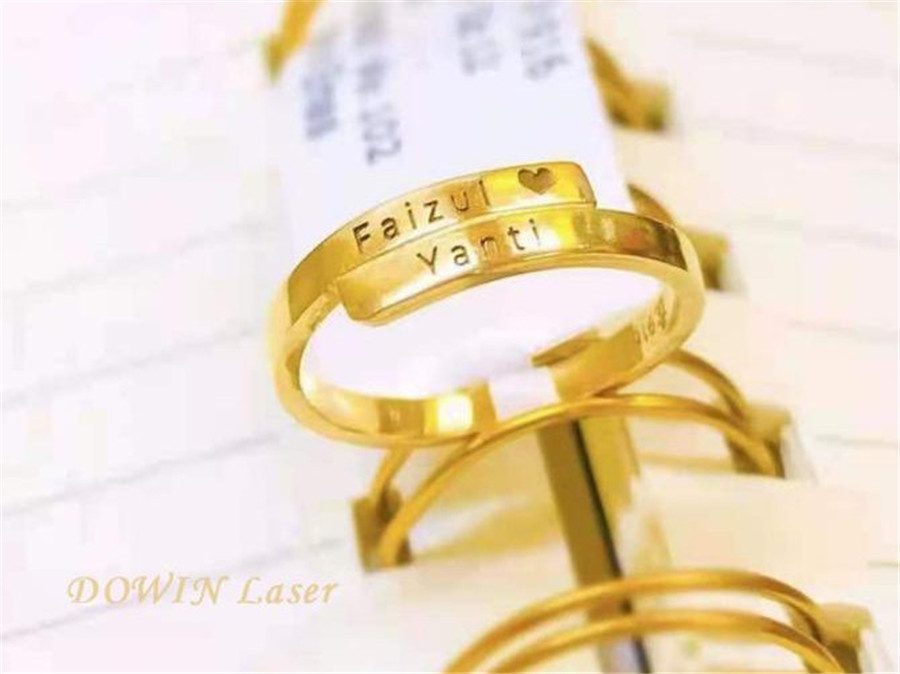

Fiber laser marking thekenoloji e khona ho tšoaea lisebelisoa tsa tšepe le lisebelisoa tse seng tsa tšepe tse sa fellang, tse loketseng masimo a mang a hlokahalang ka mokhoa o hlakileng le o phahameng haholoanyane.

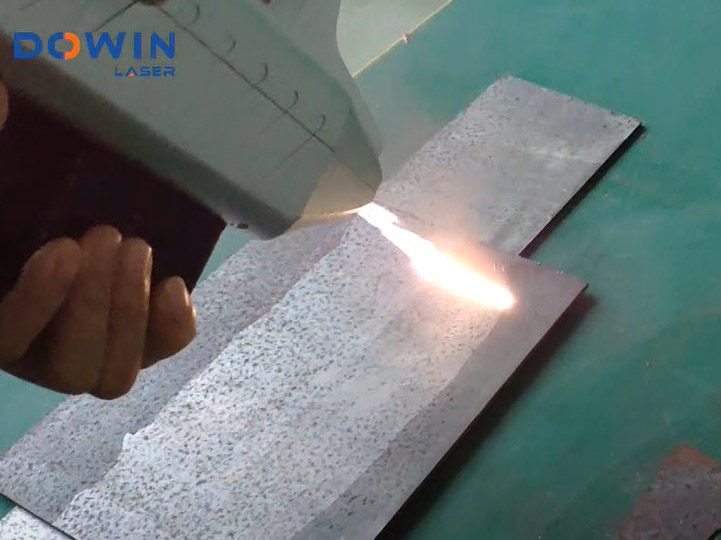

YAG welding e sebelisoang haholo bakeng sa meno a maiketsetso, mabenyane, ho lokisa hlobo le ho nchafatsa, indasteri ea ho lokisa ea "Die cast mold laser", YAG welder e kopanya le terata e tsamaisanang ea welding bakeng sa tokiso ea laser welding.Litlhoko tsa ho lokisoa ha hloboHo thatafala ka mor'a ho cheselletsa ho tšoana le hlobo ea mantlha.E khona ho lokisa li-seams tse moqotetsane, likhutlo tse bohale le li-grooves tse tebileng ntle le ho chesa likarolo tse ling.

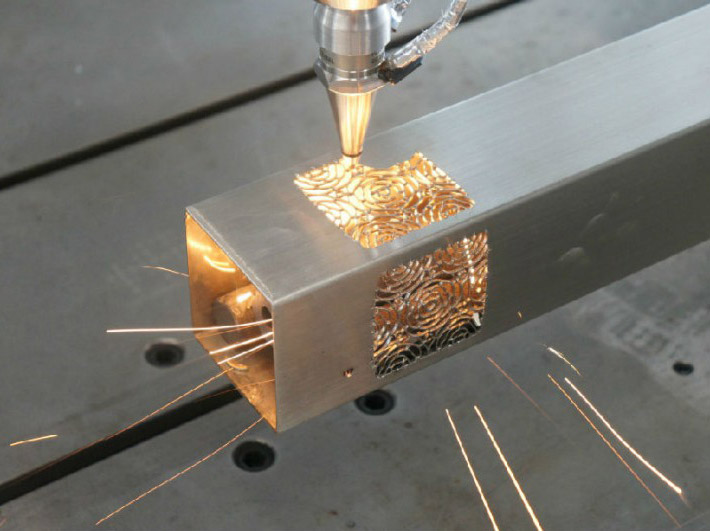

Fiber Laser cutting ke e 'ngoe ea mekhoa e sebelisoang hangata ka laser.Mefuta ea ho itšeha ka laser e arotsoe ka mekhahlelo e mene: laser vaporization cutting, laser melting cutting, laser oksijene cutting, le laser scribbling le controlled fracture.Ha ho bapisoa le mekhoa e tloaelehileng ea ho sebetsa, ho itšeha ka laser ho na le boleng bo phahameng ba ho itšeha - bophara bo moqotetsane, sebaka se senyenyane se amehileng, mocheso o boreleli, lebelo la ho itšeha ka potlako, ho feto-fetoha ha maemo ho matla - sebopeho se se nang boikaketsi se ka khaoloa ka thato, ho ikamahanya le maemo le melemo e meng.

Mochini oa ho tlosa mafome oa laser o sebelisoa indastering ea Mold,Indasteri ea lisebelisoa tsa sesole,Kaho ea likepe le boenjineri ba likepe,Moetsi oa makoloi,Mohaho oa kaho oa kantle le mesaletsa ea setso,Setsi sa matla a nyutlelie,Mechini ea kaho le indasteri e boima.