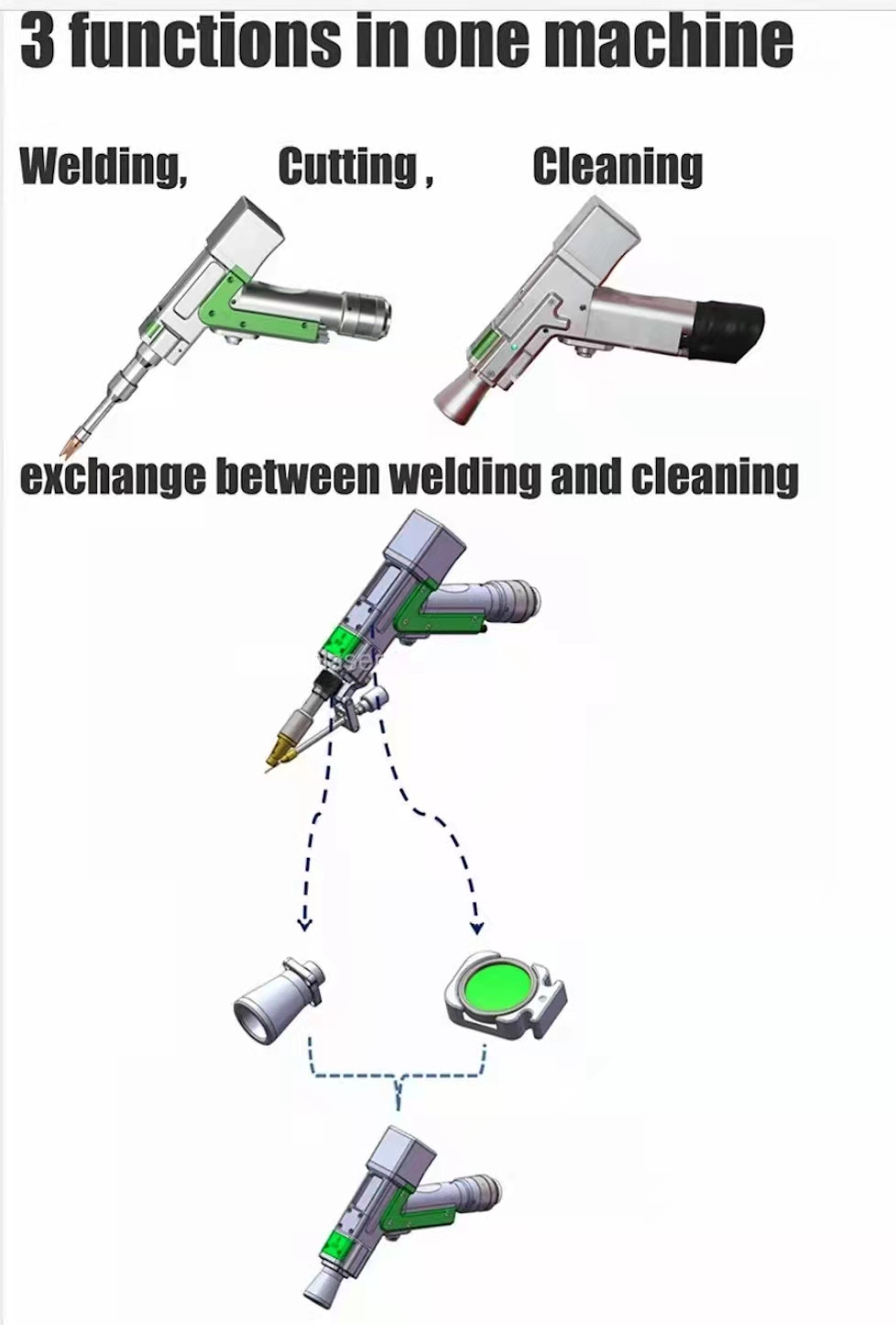

PriceList for Laser Cleaner Rust Removal - Fiber Laser welding, fiber laser cutting, fiber laser cleaning,Three in one machine – Dowin Detail:

01

Function 1: Handheld Fiber laser Welding

1. Stainless steel, stainless steel has a high coefficient of thermal expansion, which is prone to overheating during welding. When the heat affected area is slightly larger, it will cause serious deformation problems. The low heat, coupled with the relatively low thermal conductivity, high energy absorption rate and melting efficiency of stainless steel, can obtain well-formed, smooth and beautiful welds after welding.

2. Carbon steel, ordinary carbon steel can be directly welded by hand-held laser welding

3. Aluminum and aluminum alloys, aluminum and aluminum alloys are highly reflective materials. Compared with the previous metal materials, aluminum and aluminum alloys have higher parameter requirements, but as long as the selected welding parameters are appropriate, the Welds with comparable base metal mechanical properties.

4. Copper and copper alloys

5. Welding between dissimilar materials

|

Laser welding depth |

stainless steel |

carbon steel |

copper |

Aluminum |

|

1000w |

4mm |

4mm |

1mm |

2mm |

|

1500w |

5mm |

5mm |

2mm |

2.5mm |

|

2000w |

6mm |

6mm |

2mm |

3.0mm |

02

Function 2: Hand held fiber laser Cutting

Fiber cutting is used for various industries such as advertising decoration, kitchen ware, engineering machinery, steel and iron, automobile, metal plate chassis, air-conditioner manufacturing, metal plate cutting, etc.but handheld no cnc control, can only use for small amount manual cutting requirement.

03

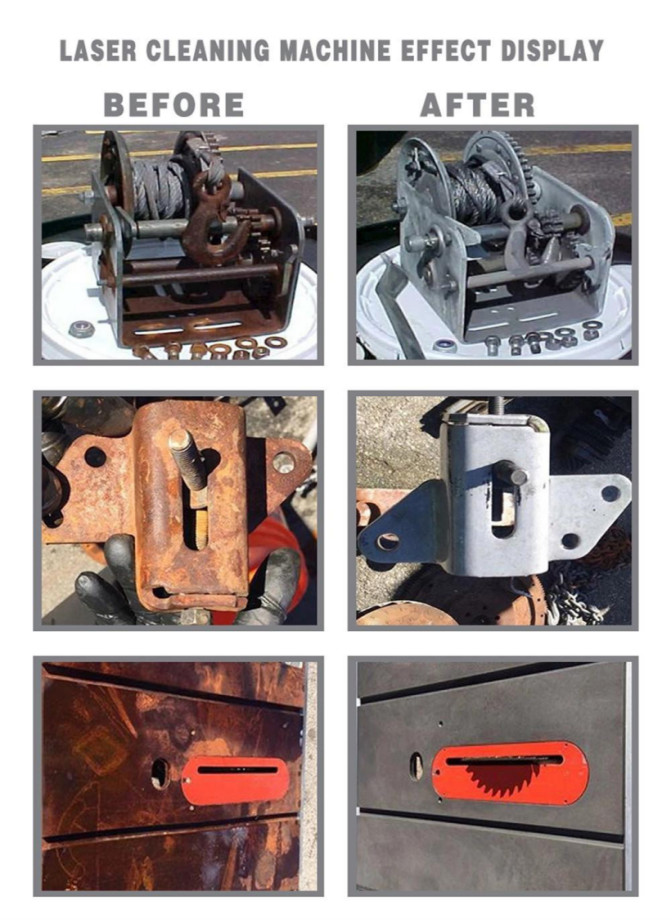

Function 3: Laser Cleaning

Laser cleaning machines can also be called laser rust removal machines. Both use high-energy laser beams to irradiate the surface of the workpiece through laser technology, so that the dirt, rust spots or coatings on the surface are instantly evaporated or peeled off, and the surface of the cleaning object is effectively removed at high speed. the attachment or coating, so as to achieve a clean process.

Some metal materials such as gold, silver, copper, iron and aluminum can be processed. Different from traditional mechanical cleaning methods, chemical cleaning methods and ultrasonic cleaning methods, it does not require any CFC organic solvents that destroy the ozone layer. It will corrode the workpiece and is harmless to the human body and the environment. It is a “green” cleaning technology. The laser cleaning machine can be used for carbon removal of pole pieces, cultural relic cleaning, clutch rust removal, weld decontamination, aircraft paint removal, and titanium alloy removal. It is used as the preferred cleaning method in occasions such as oil.

Video introduction

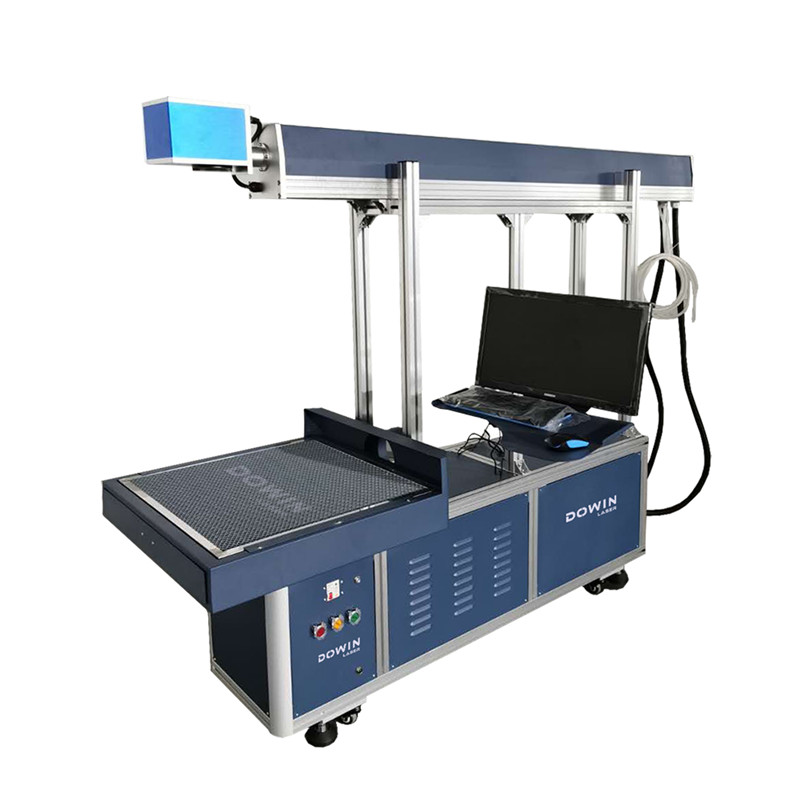

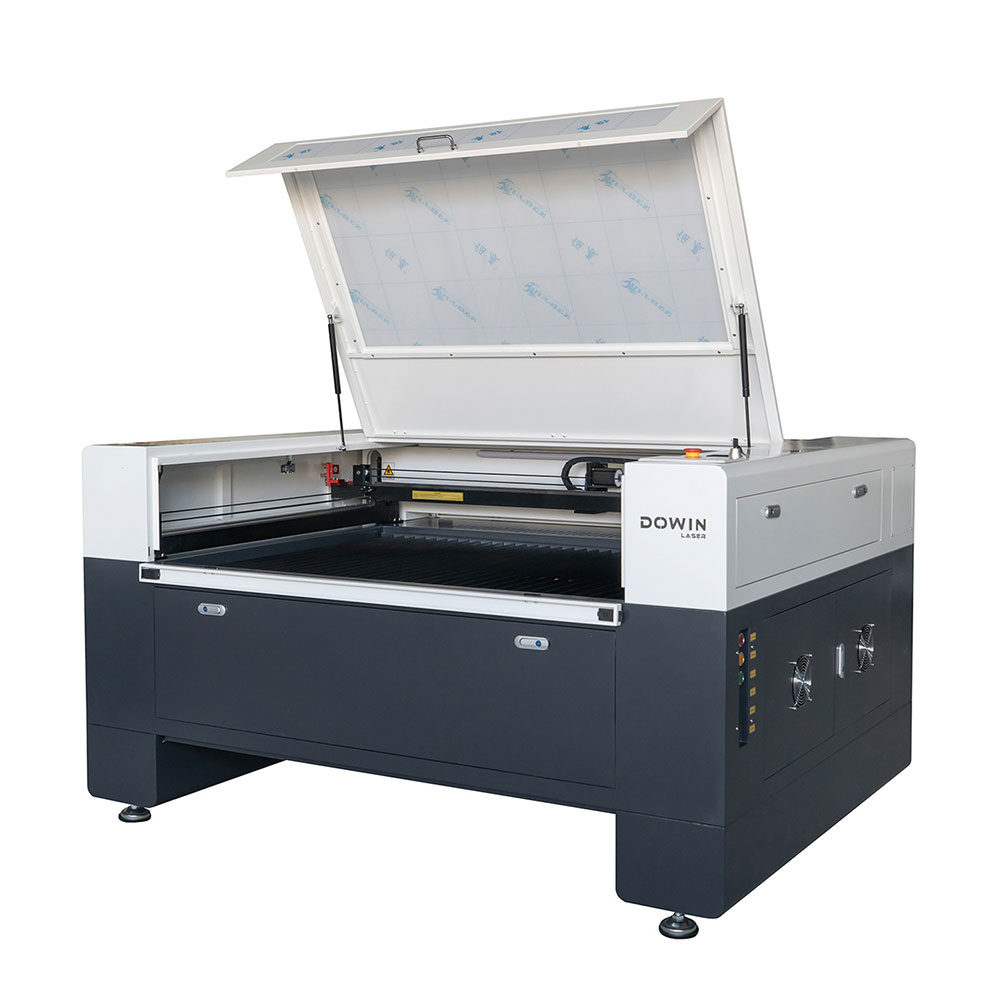

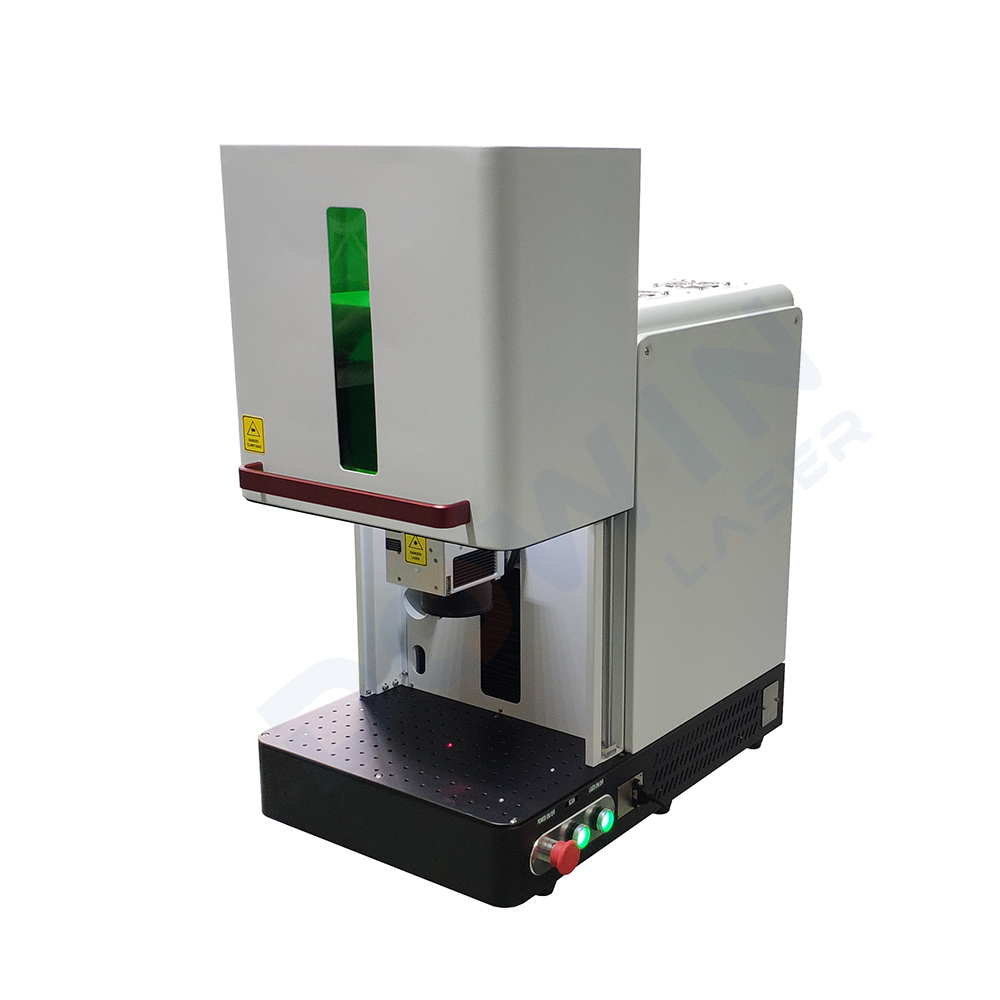

Product detail pictures:

Related Product Guide:

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for PriceList for Laser Cleaner Rust Removal - Fiber Laser welding, fiber laser cutting, fiber laser cleaning,Three in one machine – Dowin , The product will supply to all over the world, such as: Iran, Georgia, Pakistan, Our objective is to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.