Hand held fiber laser welding machine seems very easy to use ,but many clients dont know the parameters for welding different kind of materials ,and dont know why they always burn the lens protector .

Process terminology

Scan Speed: The scan speed of the motor, usually set to 300-400

Scanning width: The scanning width of the motor, according to the requirements of the weld, usually 2-5

Peak power: the actual output power during welding, the maximum is the actual power of the laser

Duty Cycle: Usually preset to 100%

Pulse frequency: usually preset 1000Hz

Focus position: the scale tube behind the copper nozzle, pull out is positive focus, inward is negative focus, usually between 0-5

Process reference

(The thicker the plate, the thicker the welding wire, the higher the power, the slower the wire feeding speed)

(Inner fillet welding is used as a reference. When other values are constant, the lower the power, the whiter the weld. When the power is higher, the weld will change from white to color.

to black, at this time it can be formed on one side)

|

Thickness |

Welding style |

Power |

width |

speed |

Wire diameter |

Wire speed |

|

1 |

Flat |

500-600 |

3.0 |

350 |

0.8-1.0 |

60 |

|

2 |

Flat |

600-700 |

3.0 |

350 |

1.2 |

60 |

|

3 |

Flat |

700-1000 |

3.5 |

350 |

1.2-1.6 |

50 |

|

4 |

Flat |

1000-1500 |

4.0 |

350 |

1.6 |

50 |

|

5 |

Flat |

1600-2000 |

4.0 |

350 |

1.6-2.0 |

45 |

The welding process of carbon steel and stainless steel is not very different, and most of the welding of aluminum plates is affected by the difference in the focus position. Please refer to the actual situation.

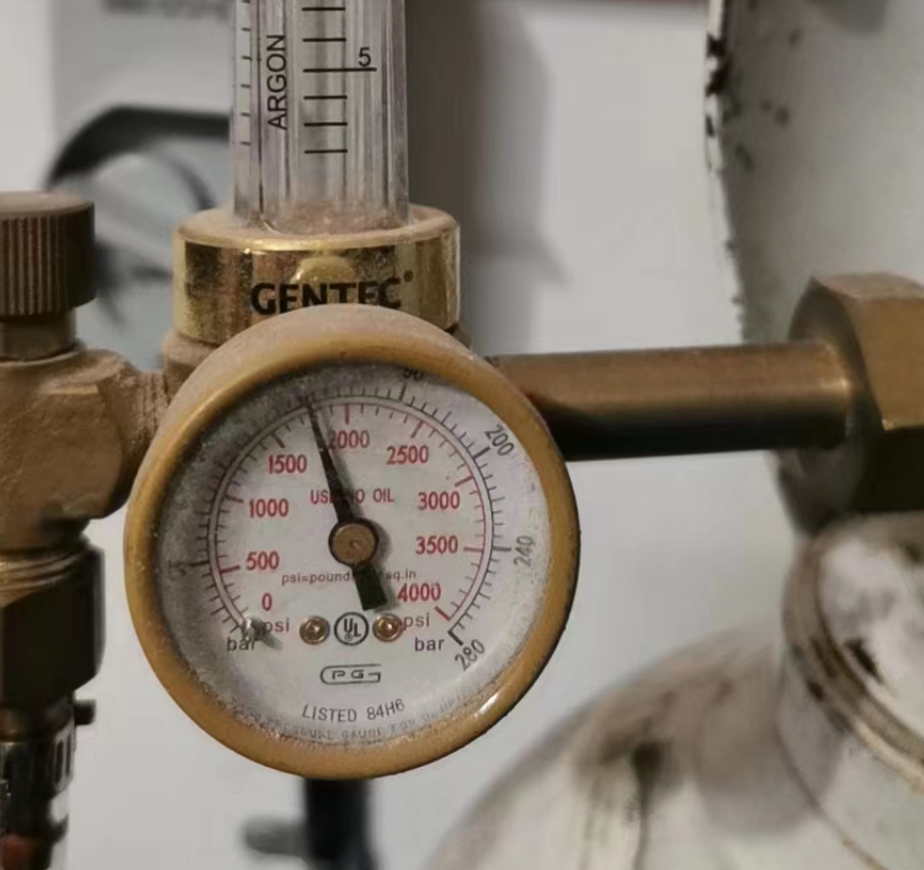

NOTE:The Fiber hand-held welding machine needs to use Argon or Nitrogen as the protective gas, the pressure is not lower than 1500psi, generally between 1500-2000psi,the protective lens will be burnt if the air pressure is low!

Post time: Aug-18-2022