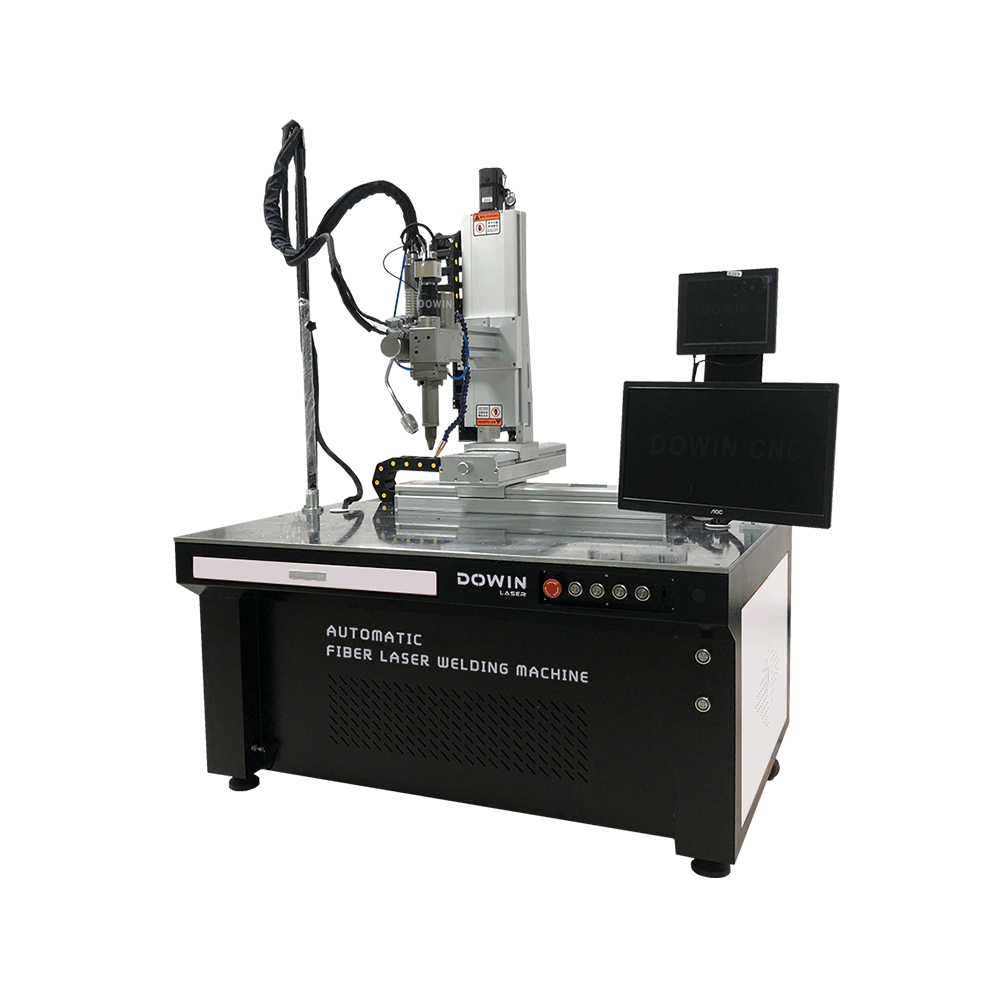

What is the advantage of Dowin jewelry laser welding machine?

01

Adopted imported ceramic condenser cavity, corrosion resistance, high-temperature resistance, long service life.The laser power feedback control system to ensure the stability of laser energy output.

02

Motic microscope observation operation,clear and more convenient for operation.

03

The diameter of the laser welding point is adjustable, and the laser welding has high precision and high accuracy.

04

YAG machine can welding narrow place, deep cavity repair welding, will not hurt the surrounding wall. It will not deform the mold product or sink around the weld pool.Make up for the short comings of traditional argon arc welding, cold welding in the repair of the fine surface of the welding

05

Special argon gas protection, control system can freely adjust the inlet and outlet time, repair welding site and substrate will not burn oxidation.When welding fine corners, it will not burn edges.

Technical parameter

| Model No. |

DW-JW 150W DW-JW 200W |

|

| Laser Source |

Nd: YAG |

|

| Laser Wavelength |

1064nm |

|

| Rated Power |

150W 200W |

|

| Laser Energy |

60J 80J |

|

| Pulse Width |

≤20ms |

|

| Pulse Frequency |

≤50Hz |

|

| Beam Diameter |

0.1-3.0mm |

|

| Power Supply |

220V±10% /50Hz |

|

| Observing System |

microscope |

|

| Chamber Illumination |

Xenon lamps |

|

| Parameters Memorization |

10 groups |

|

| Protection Alert |

flow alert |

|

| Language Display |

Chinese/English |

|

| Shield Gas Supply |

One line |

|

| Cooling System |

water cooling |

|

| Power Consumption |

5KW 6KW |

|

| Running Environment |

5℃-30℃, 5%-75% humidity |

|

| Packing size/Gross Weight |

114*69*136cm/130kg(welder)+50kg(chiller) |

|

-

Phone

-

E-mail

-

Whatsapp

-

Top