Laser engraving da yankan itace, MDF, fata, zane, acrylic, roba, filastik, PVC, takarda, epoxy guduro, bamboo.

Gilashin sassaƙa, yumbu, marmara, dutse da ƙarfe mai rufi.

Injin ƙwararren hatimi na Dowin yana amfani da ingantattun dogo na jagora da aka shigo da su daga Koriya ta Kudu wanda ƙwararren ƙwararren hatimi na Dowin ya zaɓa ya tabbatar da ingantaccen tsarin injin da kuma daidaitaccen tsari, don haka zane-zanen tambarin tambarin tambarin saman yana da ɗan lebur, ƙarfin tambarin yana da ɗanɗano iri ɗaya. kuma ba za a sami "launi bugu mai haske a tsakiya", al'amarin matsi tawada a kusa da lokacin farin ciki.

Aikace-aikacen fasahar yankan Laser a cikin masana'antar masana'anta da masana'anta ya rufe yankan, naushi, huɗawa da ƙona yadudduka da kayan haɗi.The Laser kayan aiki hadewa aiki da kai, hankali, high daidaici da kuma high dace ya dace da aikace-aikace kamar Multi-iri-iri kananan tsari samar, girgije tufafi gyare-gyare, tufafi juna yin, yankan da trimming na high-darajar yadudduka.

Yin amfani da zane-zane na Laser na iya inganta aikin zane-zane, sa saman wurin da aka zana ya zama santsi da zagaye, da sauri rage yawan zafin jiki na gilashin da aka zana, da kuma rage lalacewa da damuwa na ciki na gilashi.Ko da abin gilashin silindical ne, ana iya zana shi ta amfani da abin da aka makala na rotary.Na'urorin Laser suna da kyau don sarrafawa da ƙirƙirar kyawawan ƙirar gilashi saboda ba su da tsada, mafi sauƙi, sauri da sauƙi don aiki.

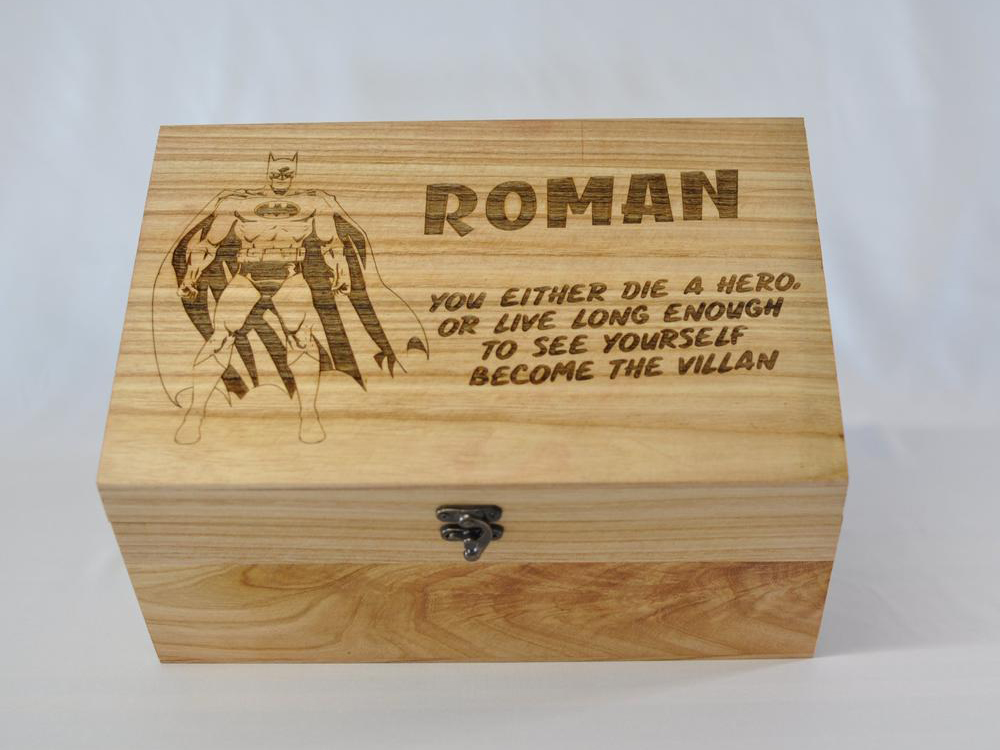

Shin kuna neman hanyoyin sassaƙa ko yanke nau'ikan itace daban-daban ko takamaiman?Itace wani abu ne mai amfani, kuma Laser sabon nau'in hanyar sarrafawa ne, kuma haɗuwarsu yana sa abubuwa da yawa suna yin sauƙi, yana ba ku damar ƙirƙirar ƙira mai ban sha'awa a kusan kowane nau'in itace.CO2 Laser cutters suna da ikon sarrafa kayan katako masu girma dabam da yawa, kamar kayan ado, kayan wasan yara, plaques, zane-zane da fasaha, abubuwan tunawa, kyaututtuka, alamu, kayan daki, gine-gine, samfura, wasanin gwada ilimi, da inlays na itace.Abin da za ku iya ƙirƙira yana iyakance ne kawai ta tunanin ku.

Laser yankan filastik da acrylic ana amfani dashi sosai a kowane fanni na rayuwa, kamar akwatunan haske, alamu, alamu, tsayawar nuni, kabad ɗin nuni, bugun kayan aiki, akwatunan marufi, kayan ado, kayan aikin hannu, da sauransu ana iya ganin rayuwa a ko'ina.The overall ingancin filastik acrylic sarrafa ta Laser sabon na'ura ne mai kyau da kuma m, da sabon surface ne santsi da kuma santsi, da engraving texture ne cikakke kuma bayyananne, da aiki format ne babba, da sauri ne sauri, da tsari ne mai sauki, da kuma yana da sauƙin aiki.Yana da cikakkiyar zaɓi don sarrafa irin waɗannan kayan.

Aikace-aikacen na'urorin yankan Laser a cikin masana'antar fata ya zama sananne sosai, kuma yawancin mutane a cikin masana'antar fata sun gane kuma sun tabbatar da su.Ya mamaye kasuwa tare da fa'idodinsa na musamman, babban madaidaici, babban sauri, ƙarancin farashi da sauƙin aiki yana sa ya shahara.Fa'idar na'urar yankan Laser ita ce ta iya yin sauri da sassauƙa da sassauƙa iri daban-daban akan yadudduka na fata daban-daban, kuma yana da sassauƙa a cikin aiki ba tare da wani nakasu na saman fata ba, don nuna launi da nau'in fata da kanta.Wannan ya sa ya dace da sauri don masana'antar sarrafa zurfin masana'anta, masana'antar kammala masana'anta, masana'antar sutura, kayan haɗin masana'anta da masana'antar sarrafawa.

An yi amfani da injin Laser sosai a masana'antar sarrafa samfuran takarda, gami da marufi, talla, masana'antar kyauta, da ƙari.Kamar katunan gaisuwa, gayyata, katunan kasuwanci, akwatunan marufi, kalmomin talla, ƙasidu, ƙasidu, na hannu da sauransu.A halin yanzu, ana amfani da kayan laser na CO2 don aiki.Dangane da halayen samfurin ku da takamaiman aikace-aikace, zamu iya samar da mafi kyawun mafita don samfuran ku.

Acrylic kuma ana kiransa plexiglass.An raba shi zuwa kayayyakin da ake shigowa da su da kuma na cikin gida.Akwai babban bambanci tsakanin su biyun.An yanke plexiglass ɗin da aka shigo da shi sosai, kuma wasu ƙazanta na cikin gida sun yi yawa, wanda zai haifar da kumfa.Za a iya sassaƙa siffofi, zane-zane ko hotuna (kamar JPG ko PNG) akan kayan tare da abin yankan Laser.A yayin wannan tsari, ana cire kayan injin ɗin da ɗan bita.Bugu da kari, ana iya zana filaye ko siffofi kamar hotuna, hotuna, tambura, inlays, kyawawan haruffa masu kauri, fuskokin tambari, da sauransu. Hakanan ana iya zana su ta amfani da wannan hanyar.Lokacin da lambar yabo ta Laser engraving da kofuna, zanen ya fito fili tare da kaifi gefuna kuma ba a buƙatar ƙarin aiki.